Ultrasonic cleaning is a process that uses high-frequency sound waves to efficiently remove dirt, grease, impurities, and contaminants from various surfaces. This technique is widely used in numerous industrial sectors and offers many advantages over traditional cleaning methods.

Have a question about any of our products listed below? Need a quote or additional information? Contact us via the menu above or the link at the bottom of this page.

OEM Ultrasonic Modules Tailored to Your Needs

Our design and development team is ready to assist with your project, offering a complete solution personalized to fit your unique needs!

Feasibility Study

Electronic Design

Software Development

Customized Transducers

Modernize Your Generators While Ensuring Backward Compatibility

Are your generators obsolete?

We develop generators that remain compatible with your old ones, thus helping you avoid replacing thousands of existing units. This allows you to upgrade your generators with new ultrasonic technology and utilize more reliable components.

Adapt Our Generators to Your Existing Transducers

Looking to upgrade your ultrasonic solutions while keeping your current transducers?

In most cases, we can adapt our generators to fit your existing setup. We offer a quick and effective solution (within just a few weeks) by incorporating the latest technologies to meet your needs.

Develop a Custom New Ultrasonic Application

Do you want to develop a new ultrasonic application? Do you need a feasibility study, prototype, or product development?

We can analyze your requirements and provide options that will meet your needs and work within your framework.

Critical Environments:

- Nuclear Radiation

- Chemistry (Acids, Bases)

- Pressure (>900 bar)

- Temperature (>700°C)

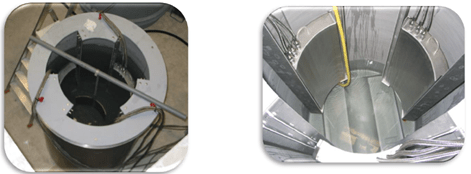

Example: Immersible ultrasonic transducers for nuclear waste decontamination tanks

Interested in our custom OEM ultrasonic modules?

Standard OEM Ultrasonic Cleaning Products

Tank Cleaning Transducers

Designed to work seamlessly with Inside and Incase generators, SinapTec’s transducers set the standard for quality with their optimized vibration amplitude and efficiency.

Those transducers can be positioned on various tank walls to optimize the cleaning of critical parts. Our products range in power from 50 Watts to 5 kW and frequencies between 22 and 100 kHz.

Learn more about our ultrasonic transducers for cleaning tanks.

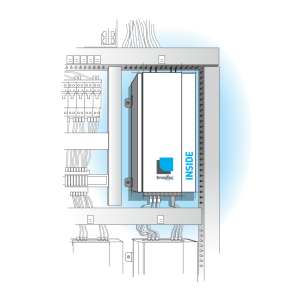

Submersible box for tanks

Paired with Inside or Incase generators, these immersible emitters are easy to install in any tank. Whether fixed in place or simply positioned, they can be replaced effortlessly. Available in a range of frequencies, these ultrasonic cleaning emitters offer versatile mounting options, including hooks, brackets, or placement directly on the tank bottom.

Tank Flanges

Transducer plates, paired with Inside or Incase generators, are fixed to the bottom or side of the ultrasonic cleaning tank. They save interior tank space and can be easily removed for replacement. This type of emitter is generally reserved for machine manufacturers who can ensure watertight and secure mounting.

Submersible rods

Linked to our generators Inside or Incase, the ultrasonic probes and rods are for radial emission designed to distribute the ultrasonic field at 360°. These ultrasonic bars offer various mounting solutions, the transducer head may be mounted either outside the bath through the wall or immersed in a waterproof manner.

Multi-frequency/multi-tank modules

The Incase 1000 model was developed to accommodate multi-frequency configurations that provide sequential frequency processing. Our technology automates cycle management for unique cleaning performance and reproducibility. An option allows for controlling multiple tanks sequentially with the same efficiency.

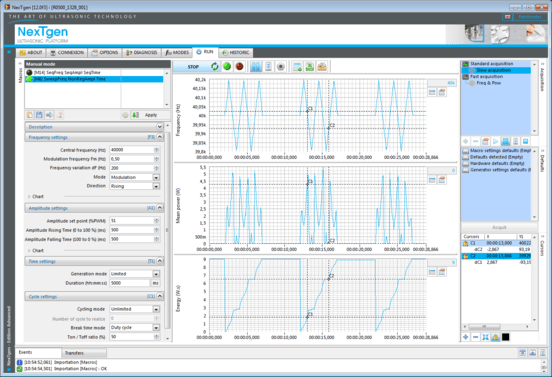

NexTgen Analyser

NexTgen ultrasonic Analyser is the device that carries out in real time the diagnostics and control of your ultrasound cleaning equipment .

All functionalities are natively integrated into our entire range of ultrasonic generators.

Paired with the NexTgen® Advanced PC software, it allows data acquisition for complete performance analysis.

NexTgen PC software

Our PC software gives you the option to select the generator’s operating mode (frequency control, sweep frequency, random frequency, multi-frequency…) and optimize the parameters to manage the ultrasonic process.

In Remote Mode, NexTgen PC Software is a unique diagnostic tool that enables online support by our after-sales service, reducing machine downtime.

How Ultrasonic Cleaning Works?

These waves, typically between 20 and 120 kHz, generate cavitation that kickstarts the creation of microscopic bubbles in the cleaning liquid. These bubbles rapidly implode, producing pressure jets that deeply remove dirt and contaminants from the surface. This method accesses hard-to-reach areas and eliminates even the most stubborn particles.

Advantages of Ultrasonic Cleaning:

– Deep Cleaning Efficiency:

Ultrasonic cleaning removes the most stubborn contaminants, even in hard-to-reach areas or narrow crevices.

– Safety and Environmental Friendliness with Chemical-Free Cleaning:

Unlike traditional cleaning methods, ultrasonic cleaning doesn’t use harsh chemicals and doesn’t damage the items being cleaned. This reduces pollution and toxic waste, for more sustainable and eco-friendly industrial practices.

– Time and Cost Savings Through Efficient Cleaning:

This technique significantly reduces cleaning time by eliminating manual scrubbing or brushing. This translates to lower labor costs and increased productivity.

– Versatility:

Ultrasonic cleaning can suit various materials, such as metal, glass, plastic, and ceramic. Its adaptability makes it useful in many industries, such as automotive, electronics, medical, jewelry, and even nuclear energy. Whether maintaining mechanical part precision, ensuring medical device purity, or restoring jewelry brilliance, each industry benefits from ultrasonic cleaning.

Applications of Ultrasonic Cleaning:

– Automotive Industry:

Ultrasonic cleaning is widely used to clean mechanical parts such as injectors, carburetors, particle filters, and more. It effectively removes carbon, oil, grease, and contaminants, enhancing component reliability and lifespan.

– Electronics Industry:

Ultrasonic cleaning removes solder flux, production residues, and grease deposits from electronic boards. It cleans even delicate, hard-to-reach areas without damage, ensuring proper function and extended lifespan.

– Jewelry:

This technique maintains the shine of precious metal jewelry (gold, silver, platinum). It effectively removes oxidation, oils, and dust, making it ideal for cleaning jewelry with gemstones like diamonds, sapphires, and rubies.

– Medical Industry:

Ultrasonic cleaning is crucial for sterilizing surgical tools, prostheses, and implants by removing biological debris and contaminants, preventing infections and ensuring patient safety.

– Nuclear Industry:

Ultrasonic cleaning removes radioactive contamination from equipment and surfaces, facilitating waste management and ensuring safe disposal.

In Summary:

Ultrasonic cleaning is an innovative and efficient solution for removing dirt and contaminants from a wide range of surfaces and materials. Ultrasound cleaning stands out for its efficiency, reliability, and the time and cost savings it provides. By choosing ultrasonic cleaning, you’re opting for one of the most effective processes, capable of tackling even the most challenging cleaning tasks.