Ultrasonic Cutting for Production Lines and Special Machines in the Food Industry

Introduction

Our ultrasonic cutting technology is particularly well-suited for food production machinery, especially in sectors such as cheese, bakery, pastry, sandwiches, and ready-made meals. Yet another ultrasonic application that delivers spectacular results, as you will see.

Cheese

Pastry

Sandwiches

Ready-made meals

The food industry now widely uses ultrasonic slicing. The process depends on a high-frequency vibrating blade while keeping its cutting ability.

Ultrasonic vibration facilitates cutting because the blade penetrates the material without deforming or compressing it while also reducing friction when in contact with the product, thereby improving both cutting quality and yield.

Ultrasonic vibration facilitates cutting as the blade penetrates the material without deforming or compressing it. It also reduces the friction between the blade and the product that is being cut, thereby, enhancing the cutting quality and quantity.

The vibrations also reduce blade contamination, improving performance and simplifying cutting tool maintenance

Operating and maintenance costs are lower than those of a mechanical blade. Ultrasonic cutting is also a great alternative to waterjet cutting which carries a risk of contamination and laser cutting which poses a risk of burns. Compared to these slicing technologies, an ultrasonic system is a cost-effective investment.

Advantages of Ultrasonic Cutting

Here are some key advantages ultrasonic food cutting has over traditional cutting methods:

🔹Precision and Cutting Quality: Ultrasonic knives produce clean and precise cuts, even with difficult-to-slice products such as soft, sticky, or layered foods. This minimizes deformation and tearing.

🔹Reduced Waste: Thanks to the precise and clean cut, there is less product loss, optimizing profitability by reducing food waste.

🔹Versatility: This technique can suit various food products like pastries, cakes, cheeses, and frozen foods. Ultrasound also enables cutting fragile products/food items or those with inclusions (fruits, nuts, chocolate) without damaging them.

🔹Preserving Texture and Shape: Ultrasonic cutting does not apply excessive pressure on the food as traditional mechanical methods do, thus preserving its original texture and shape. This is especially helpful for soft or delicate foods.

🔹Reduced Stickiness: Ultrasonic vibration significantly reduces food adhesion to the blade, a must for sticky foods such as caramels, glazed pastries, and sticky cheeses.

🔹Improved Hygiene: Ultrasonic vibrations minimize food particle buildup on the blades, reducing the risk of contamination and facilitating cleaning. This improves overall hygiene on the production line.

In summary, ultrasonic food cutting is particularly beneficial for food industry professionals looking to enhance precision, quality, and efficiency while reducing waste and tool wear costs.

Have questions about our products? Looking for a quote or more info? Contact us via the menu above or the link at the bottom of this page.

Standard OEM Ultrasonic Cutting Module

The High-Performance Solution for Machine Manufacturers

We specialize in designing, manufacturing, and supplying standard, modified, and custom ultrasonic modules, including generators, transducers, and cutting blades.

If you’re a machine manufacturer, you are likely already aware of the power of ultrasound in the food industry. In this sector, ultrasonic cutting has become a standard for quality and precision. Now is the time to take it to the next level with ultrasonic modules specifically designed to meet performance and integration requirements in your systems. Our modules, designed for the most demanding industrial environments, ensure optimized and reliable ultrasonic food cutting.

A Major Asset for Your Slicing Machines

You already understand the benefits of ultrasounds: precision, clean cuts, and handling delicate materials. Our modules take it a step further, allowing you to offer superior performance to your customers while maintaining easy integration into your equipment.

🔹Easy Integration: Designed to fit your existing systems or new developments.

🔹Precision and Hygiene: Clean cutting that meets sanitary standards, ideal for delicate and multi-layered products.

🔹Durability: Low maintenance, long blade lifespan, reduced downtime.

🔹Adaptability: Modular solutions to meet the specific needs of each production line.

Our modules are designed for effortless integration into your existing machines and production lines, whether you are developing high-speed automated equipment or more versatile machinery. They come with all the necessary technical interfaces to ensure quick and reliable integration, helping you reduce development time while guaranteeing optimal performance.

Advanced Technical Solutions for Manufacturers

We know that every machine is different and has its own set of specifications. That’s why we provide a wide range of modular configurations:

🔹Customizable blades in length, width, and format to meet your clients’ specific needs.

🔹Rotary or linear cutting options, optimizing production flow.

🔹Flexible settings to adapt to different food product densities and textures.

Our goal is to provide you with a turnkey module that is easy to integrate and configure, enhancing the competitiveness of your machines in the market.

Technical Support and Personalized Expertise

As a machine manufacturer, you already know the importance of a reliable technological partner. Our engineers can provide full technical support, from the design phase to the final integration of our modules into your systems. Our experts work closely with your teams to ensure perfect compatibility with your equipment and help you optimize the entire production process.

Stay Ahead of the Competition

In a constantly evolving market, ultrasonic cutting in the food industry represents a clear competitive advantage. By integrating our modules into your machines, you can offer your clients advanced technological solutions capable of tackling modern industry challenges: loss-free cutting, impeccable hygiene, lower operating costs, and optimized yields.

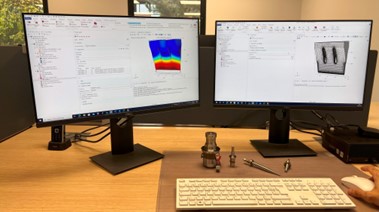

Master Your Processes with NexTgen Software

Our PC software is designed to intuitively adapt each application’s control modes and generator settings. This enables the optimization of certain parameters as well as the full control of the ultrasonic process.

NexTgen is also an innovative diagnostic tool for your ultrasonic system. It is available in two versions tailored to different uses:

Advantages:

🔹Process monitoring and verification

🔹Analysis of ultrasonic equipment performance

🔹Remote access

🔹Remote technical support

🔹History, export, traceability, and data backup

🔹RJ45 connection between PC and generator

Case Study – Brewery Filling Line

Location: Europe

Objective: Increase line speed

Context

A pastry manufacturer specializing in coated sponge cakes faced significant challenges with its cutting process. Traditional methods (mechanical blades) caused numerous issues: irregular cuts, deformation of delicate products, and frequent production shutdowns for blade cleaning, especially when handling products with a high sugar and cream content. The company sought a solution to improve product quality while optimizing its production process.

Solution

The manufacturer decided to integrate ultrasonic slicing blades into its production line. These blades use high-frequency ultrasonic vibrations to ensure clean and precise cuts, even on soft or sticky products.

Implementation

SinapTec supplied the manufacturer’s integrator with ultrasonic modules that were installed directly on the production line before the packaging stage. Thanks to advanced technology, the blades effortlessly cut through product layers without damaging or deforming delicate textures. The technology also enabled the production of uniform portions, very important for pastry presentation.

Observed Benefits

1. Superior Cutting Quality

🔹Ultrasonic blades deliver an exceptionally precise and uniform cut, even on delicate products like mousses, multi-layer cakes, and cream-based products. The edges remain intact, with no crumbling or crushing.

2. Reduced Production Waste

🔹The precision of the blades significantly reduced waste caused by imperfect cuts. Less product was discarded, increasing overall yield.

3. Productivity Gains

🔹Switching to ultrasonic blades accelerated the production process. Unlike traditional blades, which require frequent stops for cleaning, ultrasonic blades stay clean longer. Additionally, reduced downtime led to a 20% increase in production rates.

4. Lower Maintenance Requirements

🔹Traditional mechanical blades wore out quickly and needed frequent replacements, causing production interruptions. In contrast, ultrasonic blades have a longer lifespan and require far less maintenance, reducing maintenance costs.

Results

Since switching to ultrasonic slicing blades, the pastry manufacturer has seen a big boost in product quality, productivity, and cost savings on maintenance and waste. In less than a year, the investment paid for itself through increased efficiency and reduced losses. The company now plans to roll out ultrasonic blades to more production lines and strengthen its position in high-quality markets.