Ultrasonic Technology Magic: Clean Your Surfaces

Ultrasonic cleaning: a well-known technology

Ultrasound is a cleaning technology widely used in industry.

This technology creates millions of cavitation bubbles that implode on the surface of the object being cleaned. These implosions loosen the dirt and impurities accumulated on the surface.

Possible uses of ultrasound for cleaning

Ultrasound cleaning technology is exceptionally beneficial for cleaning complex objects with intricate geometries and hard-to-reach areas. The high-frequency sound waves generate microscopic cavitation bubbles in a cleaning solution. When these bubbles implode, they produce intense localized pressure and heat, which effectively dislodges contaminants from surfaces, including grooves, deep holes, narrow cracks, crevices, and gaps. This process ensures a thorough cleaning that manual or conventional methods cannot achieve. Additionally, ultrasonic cleaning is highly effective in solubilizing oils, removing rust, and disinfecting surfaces by breaking down contaminants at a microscopic level. The non-invasive nature of ultrasonic waves ensures that delicate objects are cleaned without damage, making this technology ideal for maintaining the integrity of sensitive components.

The versatility of ultrasonic cleaning extends its applications across various fields and objects. In the medical field, it is used to sterilize surgical instruments, ensuring they are free from pathogens and biological contaminants. In the automotive and aerospace industries, ultrasonic cleaning is employed to clean intricate engine parts, ensuring optimal performance and longevity. Jewelry and watchmakers use this technology to maintain the luster and functionality of delicate pieces. Additionally, it is widely used in the electronics industry to clean circuit boards and other components without causing any damage. Ultrasonic cleaning is also essential in the food and beverage industry for cleaning processing equipment, ensuring hygiene and safety. The ability to effectively clean a wide range of materials, from metals and plastics to glass and ceramics, underscores the adaptability and indispensability of ultrasound technology in modern cleaning applications.

From jewellery (bracelets, necklaces, rings, earrings, watches…) to mechanical parts, masks, musical instruments (saxophones, trumpets, flutes, etc.), airplane/motorcycle/car parts, optics, medical instruments… The list goes on, but not exhaustive.

SinapTec technology in action

Since 1984, SinapTec has been helping companies in all business areas to improve the performance and reliability of their cleaning processes by implementing and integrating our innovative and 100% French ultrasonic solutions into their existing or new production lines.

Our technology is already used in a wide range of applications, such as:

- Cleaning of vegetable seeds:

- Ensures seeds are free from dirt, pathogens, and other contaminants ;

- Promotes better growth and higher yields ;

- Essential for maintaining seed quality and integrity.

- Cleaning of horological products:

- Maintains the precision and appearance of watches and clocks ;

- Removes microscopic debris from intricate components ;

- Ensures longevity and reliable performance of timepieces.

- Cleaning of conveyor lines:

- Keeps production lines running smoothly and efficiently ;

- Removes buildup of debris and contaminants that can cause operational issues;

- Essential for maintaining high standards of hygiene in food and pharmaceutical industries.

- Cleaning of micro-tubes:

- Ensures the purity and functionality of delicate tubing used in medical and industrial applications ;

- Removes blockages and contaminants that can compromise performance ;

- Maintains the integrity and reliability of micro-fluidic systems.

- Cleaning of ophthalmic lenses:

- Maintains clarity and cleanliness in optical lenses used in eyeglasses and scientific instruments ;

- Removes oils, fingerprints, and microscopic particles ;

- Essential for ensuring optimal vision and accuracy in optical devices.

- Cleaning and unclogging of yoghurt cup modules:

- Ensures hygiene and efficiency in food production machinery ;

- Removes residues that can affect product quality and safety ;

- Maintains smooth operation and reduces downtime in dairy production lines.

- Cleaning of utensils and bottles soiled by chemical and biological products:

- Ensures safety and cleanliness in laboratory and industrial settings ;

- Removes hazardous residues to prevent cross-contamination ;

- Essential for maintaining compliance with health and safety regulations.

- … And many others:

- Our technology is versatile and can be adapted to a wide range of cleaning applications ;

- From delicate electronic components to heavy-duty industrial parts, we provide effective ultrasonic cleaning solutions ;

- Our expertise allows us to tailor our technology to meet the specific needs of various industries and applications.

Interested?

We work alongside you during your whole project

- Let’s define the solution together:

Tell us about your issues, your projects…

Let’s carry out feasibility tests.

Let’s work on a solution adapted to your requirements and your needs.

- And afterwards:

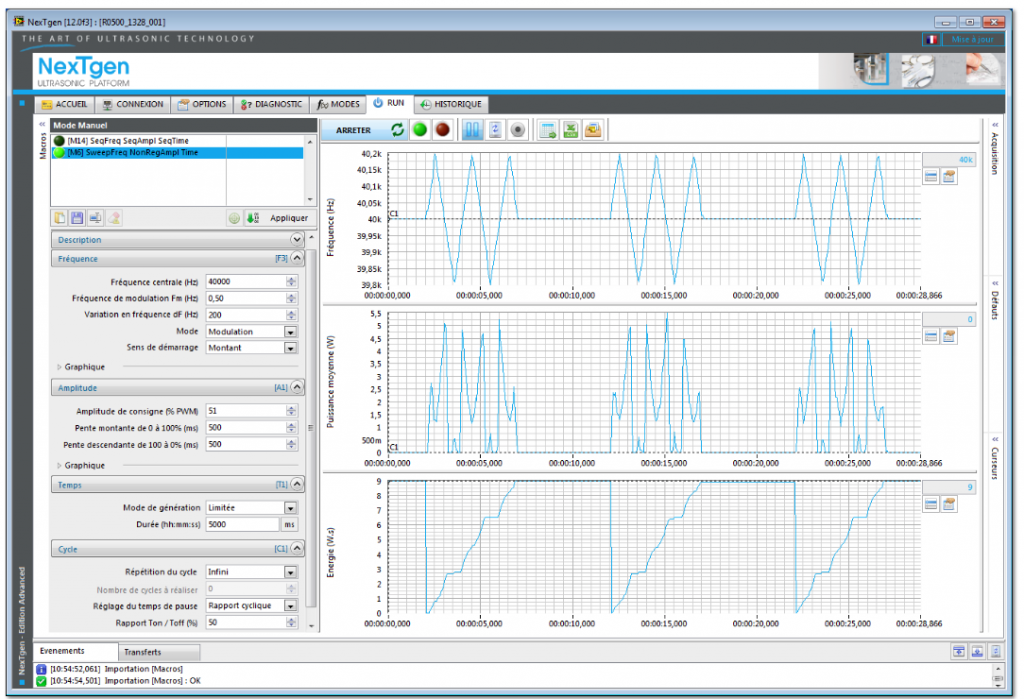

Our technology allows us to assist you remotely regardless of your location and for any request. Our technology provides you with diagnostic tools to verify the proper functioning of the equipment in real time.

So, can we help you? Contact us to find out more.

☎️ +33 (3) 20 61 03 89